Three Common cut wood to get Timber Material-Saw, Slice and Rotary

Most people are aware that wood material comes from a log. What many don’t know though is that there are three different method to cut wood to produce different results from the log and those are sawing, slicing, and using rotary.

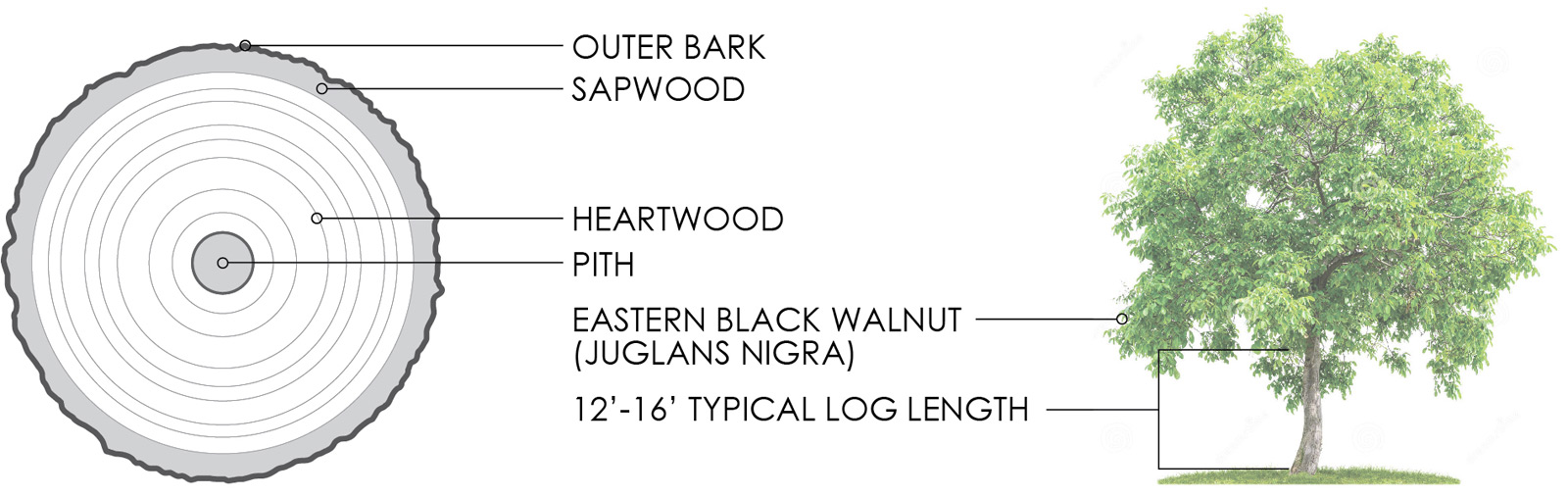

In order to understand how wood is processed from a log it’s important to know a little about the log itself. In engineered wood flooring the final function and style of the surface is directly dependent on the diameter of the log, how the log is split, and the distance between rings. Sometimes the originating tree even has to meet requirements in order to be considered for the flooring.

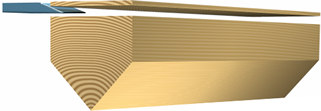

Saw Cut

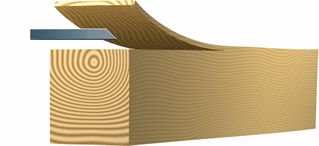

It should be noted that the saws used to extract the wood are done so after they’ve been logged out with a chain saw. The flooring manufacturers use either a circle saw, blade saw, or band saw depending on the shape of the cut they need to make.

A saw keeps the woods authentic natural look but does waste some material as the cutting motion creates saw dust.

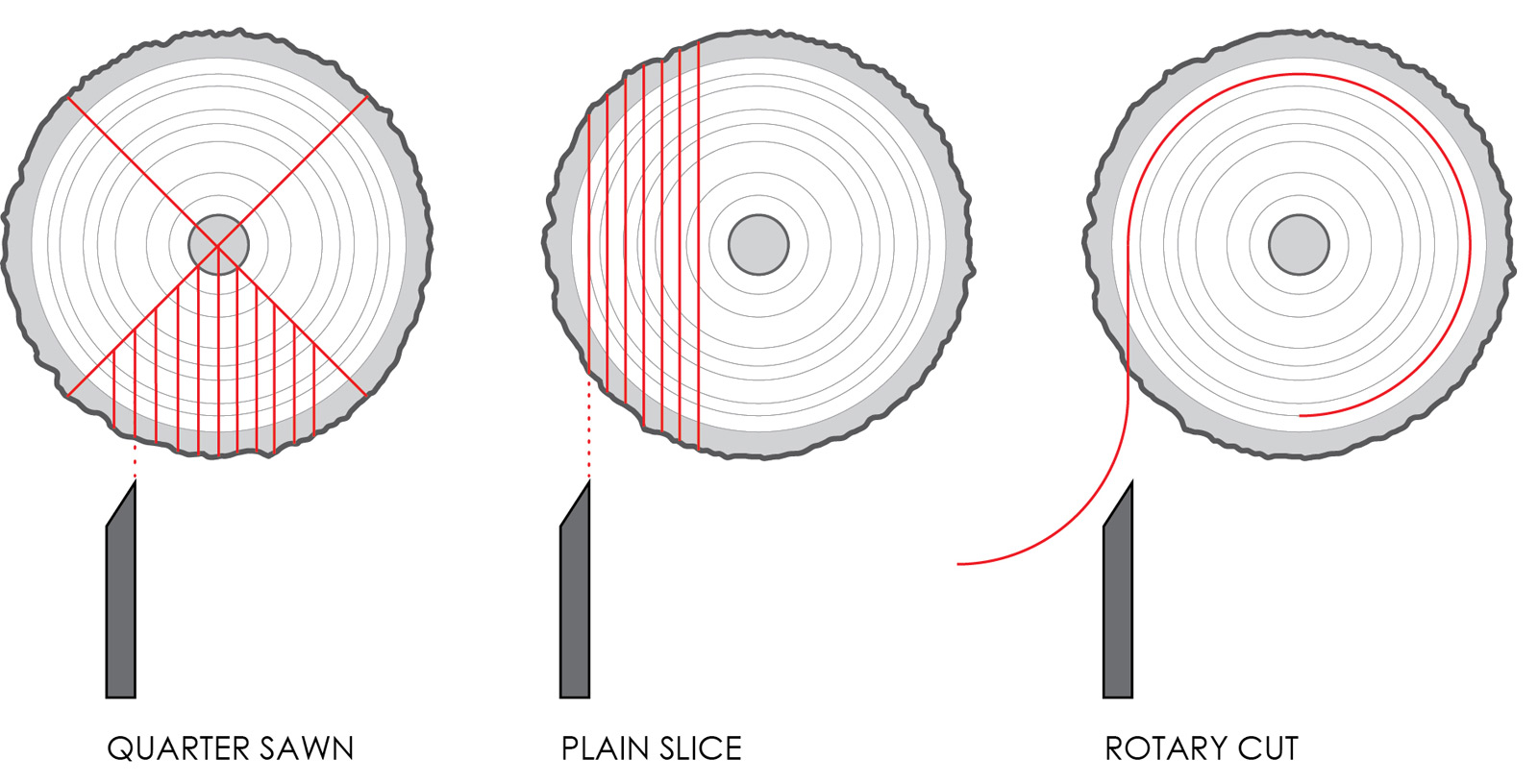

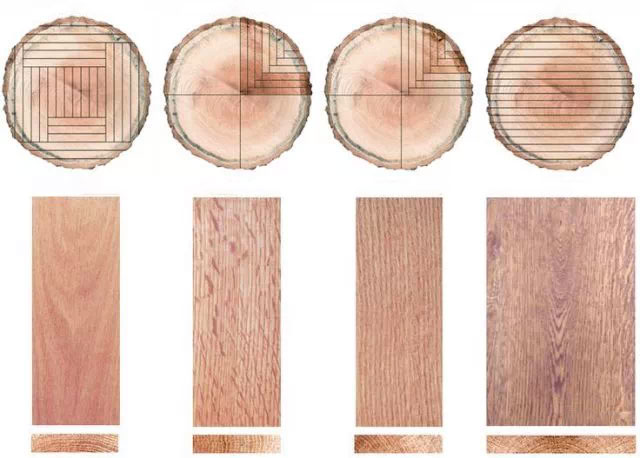

Besides using different saw types, there are also different sawing methods that will produce varying finishes. The four types are quarter, rift, plain, and live which each create different grain types.

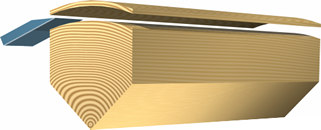

Slice Cut

The slice cut is similar to that used in meat cutting which is used to get a very thin veneer. There are still different ways within the slicing method to get different style woods:

Lengthwise Sliced Veneer

A flat piece of lumber is passed through a knife that is stationary whch produces a piece of veneer with a variegated figure.

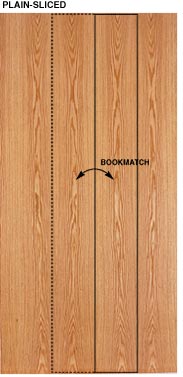

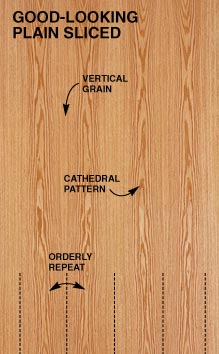

Flat Cut or Crown Cut Slice

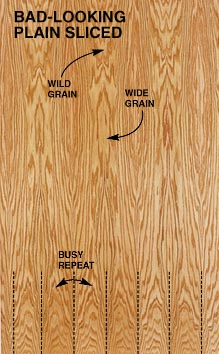

The widely used plain-sliced method involves passing half a log against a knife in an up and down motion. The cut that is produced has straight grains mixed in with cathedral peaks which creates a very natural look. The plain sliced veneer cut is available for a majority of the wood species and is moderately priced.

Half-round Sliced

A variation of rotary cutting. Segments or flitches of the log are mounted off center on the lathe. This results in a cut slightly across the annular growth rings, and visually shows modified characteristics of both rotary and plain sliced veneer.

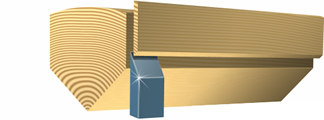

Quarter-Sliced Veneer

Similar to the half round-slice method the quarter slice also uses the up and down cutting method. The only difference is that instead of a half log the wood is cut into quarters first which gives a more straight grain look because of the lack of growth rings. Unfortunately the quarter slice doesn’t produce as much product so it is more costly and used mostly with walnut, oak, and mahogany.

A benefit of the sliced cut methods is that the don’t create any wastage because the knife is stationary instead of sliding back and forth and creating sawdust. There are disadvantages though:

- Sliced veneer are recommended to be thin in the range of 0.6mm – 2mm and can split on the surface if cut too thick.

- The logs need to be prepped by soaking in water to make it soft to cut which in turn changes the color veneer from the natural wood tone.

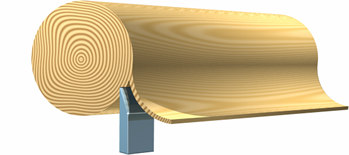

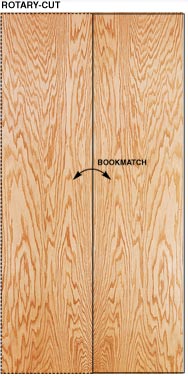

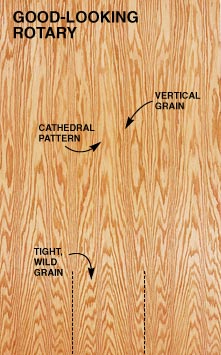

Rotary Cut

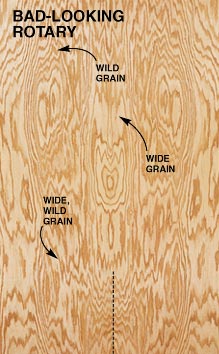

Once again the knife stays stationary but in a rotary cut the log is spun like a rotisserie pig roast. The cut follows the growth rings and creates a more prominent grain. Unfortunately the timber still needs to be soaked in water before being rotary cut but sometimes the pale wood against the deep grains creates a very unique look.

There are some definitive differences between the cuts and although rotary and half-round slice sometimes look similar, the subtleties are within the grains.

Hi.

I want to slice soft wood like poplar.

Can i get good strength.