Project Description

2-layer African Iroko Strip Flooring

Dimension

| LENGTH | WIDTH | THICK | VENEER | GRADING |

| 490 mm | 70 mm | 10 mm | 3 mm | Select / Natural |

| 450 mm | 90 mm | 10 mm | 3 mm | Select / Natural |

| 900 mm | 90 mm | 14 mm | 3 mm | Select / Natural |

| 1200 mm | 120 mm | 15 mm | 4 mm | Select / Natural / Rustic |

| Structure: | Multi-ply 6-11mm Quality Eucalyptus / Birch plywood |

| Lamination: | E0 standard Franklin cold press adhesive |

| Finish: | UV coating / Natural Oil / Hardwax Oil |

| Treatment: | Wire-Brush / Smoked / Thermo treated. |

| Joint: | 4-side Tongue and Grooves. Square Edge , Micro-bevel , Full-Bevel , Eased Bevel |

Way of Installation

Installation & Maintenance

Payment & Delivery Terms

Payment Term:

- a. Irrevocable L/C at sight.

- b. 30% downpayment, balance against copy of B/L.

Deliver time:

- For Order < 3000sqm in our regular colors, 4 weeks against downpayment.

- For Order >3000sqm or in special coating finish, 6-8 weeks upon certain product.

Manufacturing Video Tour

Strict QC System

Under the control of ISO9001, ISO14001 and ISO14025, from material to the final product, each piece is processed through 49 working procedures and each procedure is controlled strictly by certain producing data. Especially for the procedures of kiln dry skills, environmental climates and piece checking, which promise our floor with a stable and high quality.

Sanding check before UV coating. Check the surface and thickness.

UV product line check, put away the defect UV coating product.

Final product color classified secondly. Make the final packed products color in most uniform .

Advanced kiln dry skills-key factor of final floor with a stable condition.

Drying the AD board according to the different species. Different species need different way (such as; time, temperature , Moisture etc.) to dry.

Before further processing, the dried boards just after taking out from the kiln need a stress-relief period. Different species need different stress-relief time. Then the AD board turned into KD board. The stress-relief period is very important for the stability of the floor.

Moisture checking

T&G profile checking

Flatness Inspection

Square Edge

5.5mm Back Groove

Glued Plywood

Packing Dimension

| SPECIFICATION | PCS/BOX | SQM/BOX | PALLET/20FT | SQM/20FT |

| 490x70x10/3mm | 30 | 1.029 | 48 | 2263.80 |

| 900x90x10/3mm | 30 | 2.43 | 24 | 2263.80 |

| 900x90x14/3mm | 24 | 1.944 | 24 | 1492.99 |

| 1200x120x15/4mm | 16 | 2.304 | 20 | 1476.56 |

Packing Video Tour

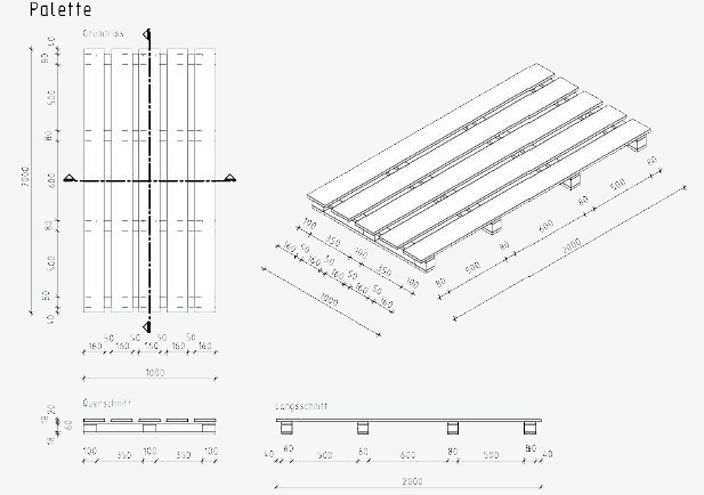

Finished engineered wood floorings are packed with OEM export paper carton packaging.

Flooring carton boxes are transmitted across through heat shrink plastic film to ensure waterproof packing system.

Packaged cartoon boxes are neatly stacked on the pallets.

Every corner and side are well protected by plastic anti-wet film and cardboard.

Then the pallets are transmitted into the warehouse , waiting for loading.

- We can design specialized OEM Package / cartons for customers according to your logo / brand.

- All pieces are covered by a plastic bag in a paper carton with Anti-wet Plastic bag Sealed.

- Loaded in Non-coniferous wood plywood (IPPC) pallets in Container.No brand on cartons.

- Products information labels on each carton and pallet.

- We design different sizes of Non-coniferous wood plywood to meet the different weight.

- Size of the cargos for the safety and convinience of the transportation and Delivery.

Container Loading Video Tour

The Forklift carries pallets one by one, and then the pallets are loaded in the container in a row skillfully.

Packaged cartoon boxes are neatly stacked on export pallets with all corner and sides well protected.

When the container is filled with pallets, close the door and seal the container. Write and remember the Seal No. and Container No.. Finally the lorry will take the container to the specified port.

Download Flooring Packing & Container Loading Capacity Spec:

- Floor Packing & Loading Specification (PDF; 65 Kb)

Visit US

Lord Parquet is located at Deqing Town, Huzhou City, Zhejiang Province in China. with 2.5 hours drive from Shanghai Pudong airport.

We are equipped with:

- Germany Homag T&G Line

- Germany Weining T&G Line

- 8 Domestic Cold Press Machine

- One UV coating line (Taiwan Fengqiao)

- One Natural Oil line (Taiwan Fengqiao)

- Eight Kiln Dry Unit (80cbm each)

- 350 workers with 2 shift

- 80,000sqm Material Warehosue

Leave A Comment