There isn’t much that adds as much value and elegance to a home than having wood flooring installed in any room. There is a certain reputation of class that comes with hardwood floors and the materials are durable, long-lasting, and match virtually any cabinet / wall paper / trim décor.

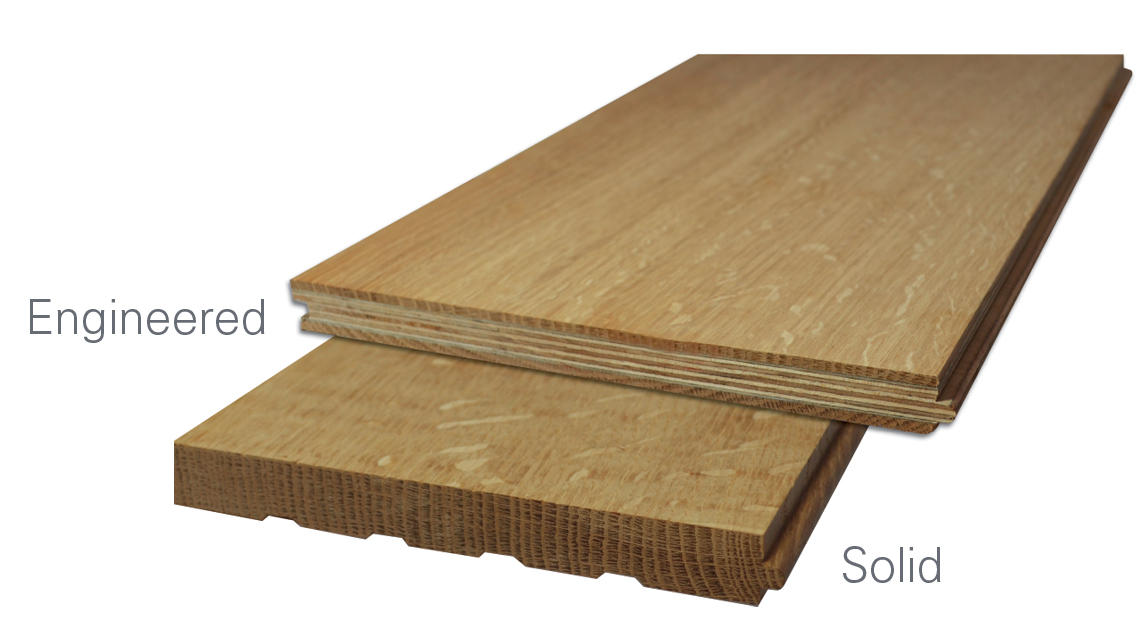

The two main types of wood flooring are solid wood and engineered wood. Solid wood, or hardwood as it’s commonly known, is a single stock piece of wood usually around 3/4” thick.

Engineered wood on the other hand is a sort of composite piece that still offers the looks of genuine wood but with a different make up. The top piece in engineered wood flooring is a very thin piece of a precious wood to supply the look of that particular species (oak, maple, ash, etc.). The inner cores consist of 3-12 layers of a birch, pine, or other common wood that is glued or pressed together for durability.

Exploring the Specific Differences Between Solid Wood Floor and Engineered hardwood flooring

Even though the two different types of flooring offer very similar benefits, they are quite different when you break down the particulars:

Structure:

When laying solid wood flooring it’s crucial to leave wide expansion gaps near the wall because the hardwood will expand and contract yearly based on changes in temperature and relative humidity. This is especially prevalent in the first year the floor is laid and can cause buckling or gaps. The expansion gaps aren’t noticeable though because they’re covered with quarter round or base trim.

Engineered hardwood flooring requires less room for shape shifting because the very premise it is manufactured consists of being bonded under heat and pressure. Engineered wood is more acclimated and resistant to changes in humidity which makes it the better option for installation below grade or in attics.

Size:

According to wood material stability principles, for most of the species, the width of a pcs of solid wood should be no more than 9 times to the thickness to ensure it’s not bowing or deforming. But normally 1 inches thick board is the biggest size workable for kiln dry process. Therefore mostly available in smaller lengths. In many cases solid wood floor pieces come in a maximum length of 3′ to 4′ which means much more piecing when installing. Solid wood flooring is also sometimes packaged in random lengths to save costs and resources so it represents a grab bag of sorts when looking for a specific length piece or trying to lay out a room.

Engineered wood flooring on the other hand since it is specially manufactured can be produced in virtually any width and length. For example, engineered wood flooring measuring 2.2 m x 260 mm (L x W) presents adequate stability provided the total thickness of wood is 20mm.

Six foot long pieces are more stable because of the cross grain manufacturing process and typically a box includes:

- (2) – 6′ engineered wood pieces

- (2) – 4′ engineered wood pieces

- (2) – 2′ engineered wood pieces

This allows easy packaging and an easier way to lay out a room for installation.

Appearance:

It’s hard to argue that solid wood flooring is one of the most elegant looks that a home can have. All that glitters isn’t gold though because the rarity which makes the floor so unique can also hinder getting enough of the same selectable grade to complete the job or to replace damaged pieces without staining and refinishing the entire floor.

Engineered wood is designed to look like a solid hardwood piece but to true flooring aficionados the difference will always be evident. The thicker the top veneer on a piece of engineered flooring the more authentic it will look but the manufactured aspect also allows for a much larger variety in finishes and sstyles.

Installation:

Solid wood flooring is slightly harder to install because each piece is nailed down to limit moving and expansion because of humidity changes. This makes the subfloor that much more important in the aspect of having wooden nail strips to shoot to or at least a completely level substrate. In lieu of nailing systems, glued down hardwood floors are becoming increasingly popular by using an elastic adhesive that doubles as a waterproof bottom layer.

One reason that engineered wood floors are so popular is because the floating install is such an easy process to master. After getting a straight starting row each subsequent piece is simply locked into place via a tongue and groove installation and the whole floor floats in uniformity. This is not only quicker to install, it helps mask some of the imperfections of the substrate below.

Maintenance

Solid wood can be brought back to life at least two and maybe three times through the years. The wood can be sanded down and refinished as long as the tongue and groove still exists which can really justify the costs of going with hardwood.

Once engineered hardwood flooring goes bad it needs to be replaced because the thin veneer on top is based on a one time use policy. This requires less maintenance but it also won’t last as long overall as solid flooring.

Eco-Friendliness

While hardwood floors in the home are nice, they don’t come without costs – usually from broadleaf trees that have acquired enough hardness which in some cases are 100 years old.

In engineered flooring only the top thin piece of veneer is made of true rare wood which greatly lightens the load on the environment. The inner core layers are made of readily available, or sustainable trees such as pine which grow for about 1/3 of the time as hardwoods.

Ultimately the final choice on which flooring to go with lies with the consumer but it’s hard to argue there’s a great case for engineered wood winning the contest.